Feeds And Speeds For Tapered End Mill . Feed to be reduced by approximately 50% if. end mill feeds and speeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. adjust the spindle speed and/or feed rate based on your cutting conditions. The following tables are starting parameters only. Every application is different and may require varying feeds. reduce speed and feed recommendations for materials harder than listed. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds.

from mavink.com

probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. Feed to be reduced by approximately 50% if. The most important aspect of milling with end mills is to run the tool at the proper rpm. adjust the spindle speed and/or feed rate based on your cutting conditions. end mill feeds and speeds. The following tables are starting parameters only. reduce speed and feed recommendations for materials harder than listed. Every application is different and may require varying feeds.

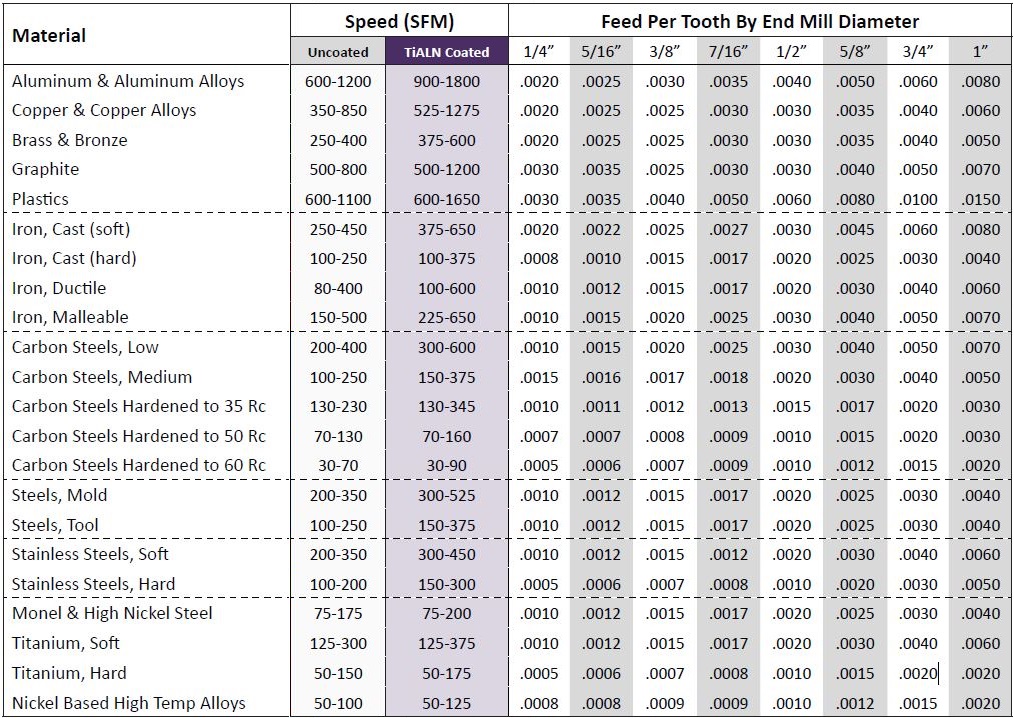

Carbide End Mill Speed And Feed Chart

Feeds And Speeds For Tapered End Mill Feed to be reduced by approximately 50% if. Every application is different and may require varying feeds. Feed to be reduced by approximately 50% if. The following tables are starting parameters only. The most important aspect of milling with end mills is to run the tool at the proper rpm. adjust the spindle speed and/or feed rate based on your cutting conditions. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. end mill feeds and speeds. reduce speed and feed recommendations for materials harder than listed.

From blog.tormach.com

Getting Started With Speeds & Feeds Feeds And Speeds For Tapered End Mill probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. The following tables are starting parameters only. Feed to be reduced by approximately 50% if. reduce speed and feed recommendations for materials harder than. Feeds And Speeds For Tapered End Mill.

From www.practicalmachinist.com

Feeds and Speeds for a 0.4mm Diameter Single Flute End Mill in PEEK Feeds And Speeds For Tapered End Mill adjust the spindle speed and/or feed rate based on your cutting conditions. Every application is different and may require varying feeds. end mill feeds and speeds. Feed to be reduced by approximately 50% if. The following tables are starting parameters only. reduce speed and feed recommendations for materials harder than listed. probably the most important factor. Feeds And Speeds For Tapered End Mill.

From www.scribd.com

Carbide End Mill Feeds and Speeds TuffCut XR 177 Metric Cast Iron Steel Feeds And Speeds For Tapered End Mill The following tables are starting parameters only. adjust the spindle speed and/or feed rate based on your cutting conditions. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. end mill feeds and speeds. reduce speed and feed recommendations for materials harder than listed. Every application is different and may. Feeds And Speeds For Tapered End Mill.

From www.qualitytechtool.com

Premium Class End Mills Metric Quality Tech Tool Feeds And Speeds For Tapered End Mill reduce speed and feed recommendations for materials harder than listed. end mill feeds and speeds. Every application is different and may require varying feeds. The following tables are starting parameters only. adjust the spindle speed and/or feed rate based on your cutting conditions. The most important aspect of milling with end mills is to run the tool. Feeds And Speeds For Tapered End Mill.

From simmonslosonfere.blogspot.com

Ball Nose End Mill Speeds and Feeds Simmons Losonfere Feeds And Speeds For Tapered End Mill Every application is different and may require varying feeds. adjust the spindle speed and/or feed rate based on your cutting conditions. Feed to be reduced by approximately 50% if. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The following tables are starting parameters only. reduce speed and feed recommendations. Feeds And Speeds For Tapered End Mill.

From www.alibaba.com

High Quality Solid Carbide Tapered End Mill With Best Speeds And Feeds Feeds And Speeds For Tapered End Mill The following tables are starting parameters only. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. adjust the spindle speed and/or feed rate based on your cutting conditions. Feed to be reduced by. Feeds And Speeds For Tapered End Mill.

From lexingtoncutter.com

Feeds & Speeds Charts Lexington Cutter Feeds And Speeds For Tapered End Mill The following tables are starting parameters only. adjust the spindle speed and/or feed rate based on your cutting conditions. end mill feeds and speeds. reduce speed and feed recommendations for materials harder than listed. Every application is different and may require varying feeds. Feed to be reduced by approximately 50% if. probably the most important factor. Feeds And Speeds For Tapered End Mill.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool Feeds And Speeds For Tapered End Mill The following tables are starting parameters only. Feed to be reduced by approximately 50% if. reduce speed and feed recommendations for materials harder than listed. adjust the spindle speed and/or feed rate based on your cutting conditions. end mill feeds and speeds. probably the most important factor affecting economical milling is the determination of cutting speeds. Feeds And Speeds For Tapered End Mill.

From solomonsisson.blogspot.com

ball end mill feeds and speeds Solomon Sisson Feeds And Speeds For Tapered End Mill adjust the spindle speed and/or feed rate based on your cutting conditions. end mill feeds and speeds. Feed to be reduced by approximately 50% if. The most important aspect of milling with end mills is to run the tool at the proper rpm. Every application is different and may require varying feeds. The following tables are starting parameters. Feeds And Speeds For Tapered End Mill.

From www.lakeshorecarbide.com

Variable Rougher Speeds & Feeds Lakeshore Carbide Inc. Feeds And Speeds For Tapered End Mill Every application is different and may require varying feeds. reduce speed and feed recommendations for materials harder than listed. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The following tables are starting parameters only. Feed to be reduced by approximately 50% if. The most important aspect of milling with end. Feeds And Speeds For Tapered End Mill.

From www.scribd.com

Speed and Feed Carbide End Mills and Drills Feeds And Speeds For Tapered End Mill Feed to be reduced by approximately 50% if. end mill feeds and speeds. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The following tables are starting parameters only. reduce speed and feed recommendations for materials harder than listed. The most important aspect of milling with end mills is to. Feeds And Speeds For Tapered End Mill.

From dxowdqrlj.blob.core.windows.net

Cobalt Roughing End Mill+Speeds And Feeds at Madeline Monico blog Feeds And Speeds For Tapered End Mill probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. end mill feeds and speeds. The following tables are starting parameters only. adjust the spindle speed and/or feed rate based on your cutting. Feeds And Speeds For Tapered End Mill.

From ar.inspiredpencil.com

End Mill Speed Chart Feeds And Speeds For Tapered End Mill reduce speed and feed recommendations for materials harder than listed. Feed to be reduced by approximately 50% if. adjust the spindle speed and/or feed rate based on your cutting conditions. The most important aspect of milling with end mills is to run the tool at the proper rpm. end mill feeds and speeds. probably the most. Feeds And Speeds For Tapered End Mill.

From mavink.com

Carbide End Mill Speed And Feed Chart Feeds And Speeds For Tapered End Mill end mill feeds and speeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. reduce speed and feed recommendations for materials harder than listed. Every application is different and may require varying feeds. Feed to be reduced by approximately 50% if. adjust the spindle speed and/or feed rate. Feeds And Speeds For Tapered End Mill.

From ar.inspiredpencil.com

End Mill Speed Chart Feeds And Speeds For Tapered End Mill adjust the spindle speed and/or feed rate based on your cutting conditions. reduce speed and feed recommendations for materials harder than listed. The following tables are starting parameters only. probably the most important factor affecting economical milling is the determination of cutting speeds and feeds. end mill feeds and speeds. Every application is different and may. Feeds And Speeds For Tapered End Mill.

From dxoefokuc.blob.core.windows.net

Osg Carbide End Mills Speeds And Feeds at Damion Hoffman blog Feeds And Speeds For Tapered End Mill The most important aspect of milling with end mills is to run the tool at the proper rpm. Feed to be reduced by approximately 50% if. end mill feeds and speeds. The following tables are starting parameters only. reduce speed and feed recommendations for materials harder than listed. adjust the spindle speed and/or feed rate based on. Feeds And Speeds For Tapered End Mill.

From conicalendmills.com

Conical Tool Speed & Feeds Tapered End Mills, Cutting Tools Feeds And Speeds For Tapered End Mill end mill feeds and speeds. reduce speed and feed recommendations for materials harder than listed. adjust the spindle speed and/or feed rate based on your cutting conditions. Every application is different and may require varying feeds. The most important aspect of milling with end mills is to run the tool at the proper rpm. The following tables. Feeds And Speeds For Tapered End Mill.

From www.qualitytechtool.com

General Purpose End Mills Metric Quality Tech Tool Feeds And Speeds For Tapered End Mill Feed to be reduced by approximately 50% if. Every application is different and may require varying feeds. The following tables are starting parameters only. The most important aspect of milling with end mills is to run the tool at the proper rpm. reduce speed and feed recommendations for materials harder than listed. probably the most important factor affecting. Feeds And Speeds For Tapered End Mill.